18-Litre Autoclave of Class B in Green

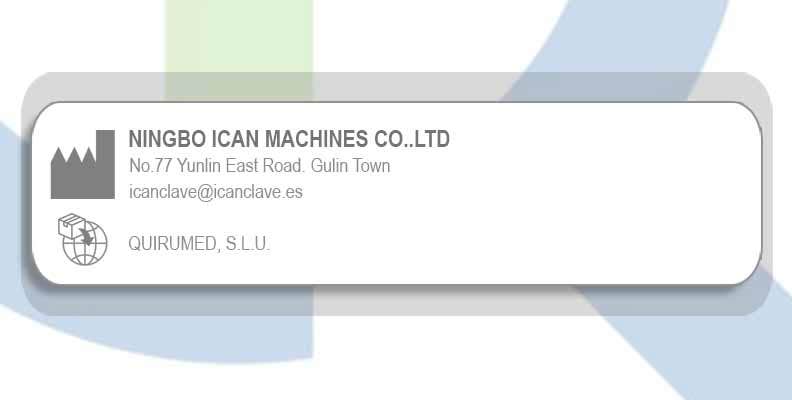

Manufacturer Information:

Name or company: Pending update

Email: Pending update

Postal address: Pending update

City: Pending update

Country: Pending update

Responsible person information:

Name or company: Pending update

Email: Pending update

Postal address: Pending update

City: Pending update

Country: Pending update

Warnings and product safety information:

The product complies with the General Product Safety Regulation.

Autoclave for the seterilisation of great variety of load. 18-litre capacity, Class B, double security closing, and USB port. Finishings in bright green colour.

Programmes:

| Programmes: | Temperature: | Pressure: | Sterilisation time | Total time | Type | Maximum load | Maximum load per tray |

|---|---|---|---|---|---|---|---|

| Solid | 134 ºC | 210 kPa | 4 min | 20-35 min | Solid material without wrapping | 4.5 Kg | 1.2 Kg |

| 121 ºC | 110 kPa | 20 min | 30-50 min | ||||

| Wrapped | 134 ºC | 210 kPa | 4 min | 30-50 min | Solid material without wrapping | 4.5 Kg | 1.2 Kg |

| 121 ºC | 110 kPa | 20 min | 35-55 min | Solid or empty material with simple wrapping | 3.5 Kg | 1.1 Kg | |

| Liquid | 134º C | 210 kPa | 10 min | 30-55 min | Liquid | 1 Kg | 0.3 Kg |

| 121º C | 110 kPa | 30 min | 35-60 min | ||||

| Textile | 134 ºC | 210 kPa | 8 min | 40-65 min | Porous material without wrapping | 1 Kg | 0.3 Kg |

| Porous material with simple wrapping | 0.80 Kg | 0.25 Kg | |||||

| Porous material with double wrapping | 0.6 Kg | 0.2 Kg | |||||

| 121 ºC | 110 kPa | 30 min | 45-75 min | Empty material with simple wrapping | 3.5 Kg | 1.25 Kg | |

| Solid or empty material with double wrapping | 1.5 Kg | 0.6 Kg | |||||

| Prion | 134 ºC | 210 kPa | 18 min | 45-70 min | Porous material without wrapping | 1 Kg | 0.3 Kg |

| Porous material with simple wrapping | 0.75 Kg | 0.25 Kg | |||||

| Porous material with double wrapping | 0.6 Kg | 0.2 Kg | |||||

| Empty material with simple wrapping | 3.5 Kg | 1 Kg | |||||

| Solid or empty material with double wrapping | 1.5 Kg | 0.5 Kg | |||||

| B&D Test | 134 ºC | 210 kPa | 3.5 min | 22-35 min | - | - | - |

| Helix Test | 134 ºC | 210 kPa | 3.5 min | 22-35 min | - | - | - |

| Vacuum Proof | - | - | - | 15-20 min | - | - | - |

- The minimum time required for the autoclave to be ready for being used after connecting it tho the power supply is 5 minutes.

- The maximum temperature of the 134 ºC sterilisation cycle is 137 ºC

- The maximum temperature of the 121 ºC sterilisation cycle is 124 ºC

Features

- Completely automatic with pre-programmed sterilisation cycles.

- Chamber and door made of stainless steel with electropolished finishing.

- High-precision control system for perfect sterilisation results.

- User-friendly interface.

- LCD display: it continually shows information on the process of the cycles.

- Open-type water tank. This feature makes easier filling it with water and cleaning it. IMPORTANT: Do not reuse the water of the waste deposit.

- Optional printer (not included. Reference 922-PRINTER04).

- Languages: Spanish, English, German, French, Italian, Dutch, Polish, Romanian, Czech, Latvian, Lithuanian, Hungarian and Chinese.

Safety devices:

- Circuit breaker.

It protects the equipment from any possibility of failure in the electricty system.

Action: Interrupting the energy supply. - Fuses.

Protection against possible short-circuits and overheating in the primary network of the transformer.

Action: Temporary interruption (until the temperature has decreased) in the set of bobbins. - Safety valve.

Protection against a possible increase in pressure inside the chamber.

Action: Steam exhaust until recovering a normal level pressure. - Micro-switch to control the state of the door.

It exercises control in the doord adjustment to be able to start a sterilisation cycle.

Action: It transmits the signal to alert on the incorrect position of the door. - Thermostat for the resistors in the steam generator.

Protection before a possible overheating in the resistors in the steam generator.

Action: It interrupts the power supply towards the resistors in the steam generator. - Thermostat for the resistors in the chamber.

Protection before a possible overheating in the resistors in the steam generator.

Action: It interrupts the power supply towards the resistors in the chamber. - Self-levelling of the hydraulic system.

The hydraulic system will bring back its natural pressure if the sterilisation cycle has been interrupted manually.

Action: The internal pressure will be restored automatically. - Blocking of the door

Effective protection to prevent the door from opening accidentally.

Action: It prevents the door from opening through a blocking hydraulic system.

Technical features:

- Nominal voltage: 220-240V; 50/60 Hz; 10A

- Dimensions of the chamber: 247 × 350 mm

- Circuit breaker: F16A / 400V

- Nominmal power: 2200 VA

- Sterilisation temperature: 121 ºC / 134 ºC

- Capacity of the distilled water tank: 2.5 L approx.

- Operation temperature: 5 ºC / 40 ºC

- Relative huimidity of the operation: Max. 80 %, non condensing

- Exterior size: 480 × 455 × 600 mm

- Net weight: 47 Kg

- Maximum level of noise: <70 dB

- Atmospheric pressure of operation: 76 / 106 kPa

Components:

- Distilled water tank:

- LCD screen.

- Control panel.

- Main switch.

- Key for drainage of distilled and used water.

- USB port.

- Safety valve.

- Ventilation grille.

- Blocking system.

- Power cord.

Included accesories:

- Tools trays (3).

- Base for trays.

- USB memory.

- Handle for extracting the trays.

- Adjustment tool for the door.

- Drainage hoses (2).

- Gasket for the door.

Optional and spare accessories:

- 922-PRINTER04 Printer for autoclave.

Autoclave process step by step:

1- Open de door, pick up the tools and accesories that are inside the sterilisation chamber, remove the wrapping and clean them.

2- Connect hte power cord to a proper power supply.

3 - Connect the printer (optional accesory, it is sold separately. If you want to acquire it, look in this website for the reference 922-PRINTER04).

4- Start: The main switch is located at the lower-front side of the equipment, on the right.

- Once activated, the LCD screen will illuminate, where the basic functioning icons of the steriliser are displayed, as well as the position of the door, the water level, the sterilisation programme, the date, the hour, etc.

5- Fill the tank with distilled water.

- Remove the upper lid of the tank and proceed to filling it. If you hear a signal, that means that you exceeded the allowed water level in the tank. So, please, stop immediately and drain how much water is needed to turn the signal off.

6- Preparation of the material that is going to be sterlised:

- Place the tools made of different material in different trays. Make sure you separate them well before sterilising them.

- If the tools are not made of stainless steel, interpose paper for sterilisation between the tray and the tools.

- Do not allow direct contact between instrument of different material.

- Verify that all the tools are in the correct position.

- Place on the tray tools such as lenses, recipients, tubes, etc. in inverted position, so the water does not get stuck in them.

- Do not overload the trays beyond its capacity.

- Do not place the trays one over the other, nor put them in direct contact with the wall of the sterilisation chamber.

- Do not use metal clips nor pins, since it can endanger the functioning of the steriliser.

7- Select the sterilisation programme.

8- Start the sterilisation cycle.

- After having selected the sterilisation programme, introduce the tools in the chamber using the trays with the provided plastic handle.

- Once the tools are inside the chamber, close the door.

- Warning: Make sure of properly closing the door. If not, the steriliser will show an alarm and will not be able to start the programme or it will stop during the cycle.

9- Start the sterilisation programme.

- Press the start button. Then, the steriliser will start functioning during, approximately, 30-75 minutes.

10- Sterilisation cycle finished.

- Once the sterilisaton cycle has finished, the printer (optional accesory with reference 922-PRINTER04) will automatically print the complete report of the cycle.

- After the pressure descends to zero, you could open the door and extract the tools. The steriliser will alert through a sound alarm when the sterilisation cycle finishes.

- Warning: Whenever you are going to extract the tools, use the provided plastic handle for the trays support.

IMPORTANT: Do not reuse the water of the waste deposit.

Installation:

- There must be at least 10 cm free space around the steriliser, 25 cm on the upper part, and enough space so that the door can open completely.

- The place where the steriliser operates must have a proper ventilation.

- The steriliser must be placed on a table that resists the weight and at a proper level for its handling.

- Do not cover nor block the side outputs, nor the grille output of the fan air flow of the condenser.

- Do not place the steriliser close to water sources to prevent splattering.

- Keep it far from other heat sources.

Example of a printed report*:

* The printer is an optional accesoroy and is sold separately with the reference 922- PRINTER04.

================================

Programme: WRAPPING

Temperature: 134C

Pressure: 206.0 kPa

Drying time: 08Min

Sterilisation time: 4.0Min

--------------------------------

Time Pressure Temperature

Start 12:28:17 089.0C

T1: 12:31:32 087.1C -075.0kPa

T2: 12:33:43 110.2C 052.0kPa

T3: 12:36:37 088.9C -080.0kPa

T4: 12:39:20 114.7C 053.7kPa

T5: 12:43:37 087.9C -080.0kPa

T6: 12:50:40 134.8C 206.0kPa

TS: 134.7C 209.5kPa

Max. Temperature :135.2C

Min. Temperature:134.3C

Max. Pressure: 214.0kPa

Min. Pressure: 204.9kPa

T7: 12:54:39 134.4C 211.4kPa

T8: 12:57:36 102.1C -060.0kPa

T9: 12:59:54 098.2C -060.0kPa

End 13:04:07 102.4C

--------------------------------

Cycle No.: 00017

Result: success

Date: 2014-06-07

SN:E54723

Operator:

================================

Directive:

- 93/42/CEE Medical devices directive.

- 97/23/CEE Pressure equipments directive.

- EN 13060 Small steam sterilisers

- EN 61326, EN 61000 Electromagnetic compatibility.

- EN 61010-1, UL 61010-1 Safety requirements.

- EN 61010-2-040, IEC 61010-2-040 Specific requirements for steam sterilisers used for medical devices treatments.

In the UK this product needs to be inspected and certified anually. Quirumed don´t offer this service and you will need to find your own local techncian who can do this.

Video: